Gautham Shah

Visakhapatnam, Visakhapatanam

Gautham Shah

2 years ago

Unveiling the Marvels of MS Sheets: A Comprehensive Guide

Introduction:

MS Sheets have become indispensable in various industries, playing a crucial role in construction, manufacturing, automotive, and beyond. One of the most widely used types of metal sheets is Mild Steel (MS) sheets. In this comprehensive guide, we'll delve into the world of MS sheets, exploring their properties, applications, and the reasons behind their widespread popularity.

Understanding MS Sheets:

1. Composition and Properties:

Mild Steel, also known as low carbon steel, is primarily composed of iron and a small percentage of carbon. This composition provides MS sheets with unique characteristics such as ductility, weldability, and versatility. MS sheets typically have a carbon content ranging from 0.05% to 0.25%, making them suitable for a wide range of applications.

2. Types of MS Sheets:

MS sheets come in various types, including hot-rolled, cold-rolled, and galvanized sheets. Hot-rolled MS sheets are produced at high temperatures, making them ideal for structural applications. Cold-rolled sheets undergo processing at lower temperatures, resulting in smoother surfaces and tighter tolerances. Galvanized sheets are coated with a layer of zinc to enhance corrosion resistance.

Applications of MS Sheets:

1. Construction Industry:

MS sheets find extensive use in the construction sector for manufacturing beams, columns, and other structural elements. Their high strength and durability make them an excellent choice for building frameworks.

2. Automotive Manufacturing:

In the automotive industry, MS sheets are employed to fabricate various components, including car bodies, chassis, and panels. Their formability and weldability contribute to the efficiency of manufacturing processes.

3. Fabrication and General Engineering:

MS sheets are widely used in fabrication and general engineering due to their versatility. From creating machine parts to manufacturing everyday items, the adaptability of MS sheets makes them a preferred material.

Advantages of MS Sheets:

1. Cost-Effective:

Mild Steel is relatively inexpensive compared to other types of steel, making MS sheets a cost-effective choice for many applications.

2. Formability and Weldability:

MS sheets are known for their excellent formability, allowing for easy shaping and fabrication. Additionally, they are highly weldable, making them suitable for various joining techniques.

3. Strength and Durability:

With adequate strength and durability, MS sheets offer reliable performance in diverse conditions. This makes them suitable for both indoor and outdoor applications.

Conclusion:

MS Sheets are an integral part of numerous industries, contributing to the creation of structures, vehicles, and everyday products. Their versatile nature, coupled with cost-effectiveness and desirable properties, has solidified their position as a preferred material in the world of metal fabrication. As technology advances, the applications and innovations surrounding MS sheets are likely to expand, further showcasing the enduring significance of this humble yet robust material.

#ms sheets , #mild steel sheets , #buy ms sheets online

0 likes · 0 comments

BusinessGautham Shah

2 years ago

The Marvels of Galvanized Sheet: A Closer Look at its Uses and Advantages

Introduction:

Galvanized sheets are a ubiquitous yet often overlooked material that plays a crucial role in various industries and applications. This article aims to shed light on the wonders of galvanized sheets, exploring their composition, manufacturing process, and the wide range of uses they serve in construction, manufacturing, and beyond.

What is Galvanized Sheet?

Galvanized sheet, also known as galvanized steel, is a steel sheet coated with a layer of zinc to enhance its corrosion resistance. The process of galvanization involves immersing the steel sheet in a bath of molten zinc or electroplating it with zinc. This coating acts as a protective barrier, preventing the underlying steel from rusting and corroding, even in harsh environments.

Composition and Manufacturing:

Galvanized sheets are typically made from hot-dip galvanized steel or electro-galvanized steel. Hot-dip galvanizing involves immersing the steel in a bath of molten zinc, while electro-galvanizing uses an electrolytic process to deposit a thin layer of zinc onto the steel surface. The zinc coating adheres tightly to the steel, creating a durable and effective protective layer.

Advantages of Galvanized Sheets:

Corrosion Resistance:

The primary advantage of galvanized sheets is their exceptional resistance to corrosion. The zinc coating acts as a sacrificial anode, corroding preferentially to protect the underlying steel. This makes galvanized sheets ideal for outdoor and industrial applications where exposure to moisture and harsh elements is common.

Longevity:

Galvanized sheets have a longer lifespan compared to untreated steel. The corrosion-resistant properties of the zinc coating contribute to the durability of the material, reducing maintenance costs and extending the life of structures and products.

Versatility:

Galvanized sheets find applications in a wide range of industries, including construction, automotive, agriculture, and manufacturing. They are used to make roofing materials, fencing, HVAC ducts, automotive parts, and various other products where corrosion resistance is essential.

Ease of Fabrication:

Galvanized sheets are easy to work with and can be cut, formed, and welded without compromising the integrity of the zinc coating. This makes them a preferred choice for manufacturers and builders looking for a versatile and user-friendly material.

Aesthetic Appeal:

In addition to their functional benefits, galvanized sheets offer a distinctive aesthetic appeal. The shiny, spangled surface of galvanized steel adds a unique visual dimension to structures, making them stand out.

Applications of Galvanized Sheets:

Roofing and Cladding:

Galvanized sheets are commonly used for roofing and cladding in residential, commercial, and industrial buildings due to their weather resistance.

Automotive Industry:

Galvanized steel is widely used in the automotive sector for manufacturing body panels, chassis components, and other parts requiring corrosion resistance.

Construction:

From structural components to fencing and handrails, galvanized sheets play a crucial role in construction for their durability and resistance to environmental factors.

Agricultural Equipment:

Farm equipment, such as grain bins, silos, and fencing, often incorporates galvanized sheets to withstand the rigors of outdoor exposure.

Conclusion:

Galvanized sheets are a testament to the marriage of science and industry, providing a cost-effective and reliable solution for corrosion resistance in various applications. As we continue to explore innovative materials, the enduring appeal and utility of galvanized sheets remain steadfast, contributing to the longevity and sustainability of diverse structures and products across the globe.

#galvanizedsheet , #buy galvanized sheet , #best quality galvanized sheet

0 likes · 0 comments

BusinessGautham Shah

2 years ago

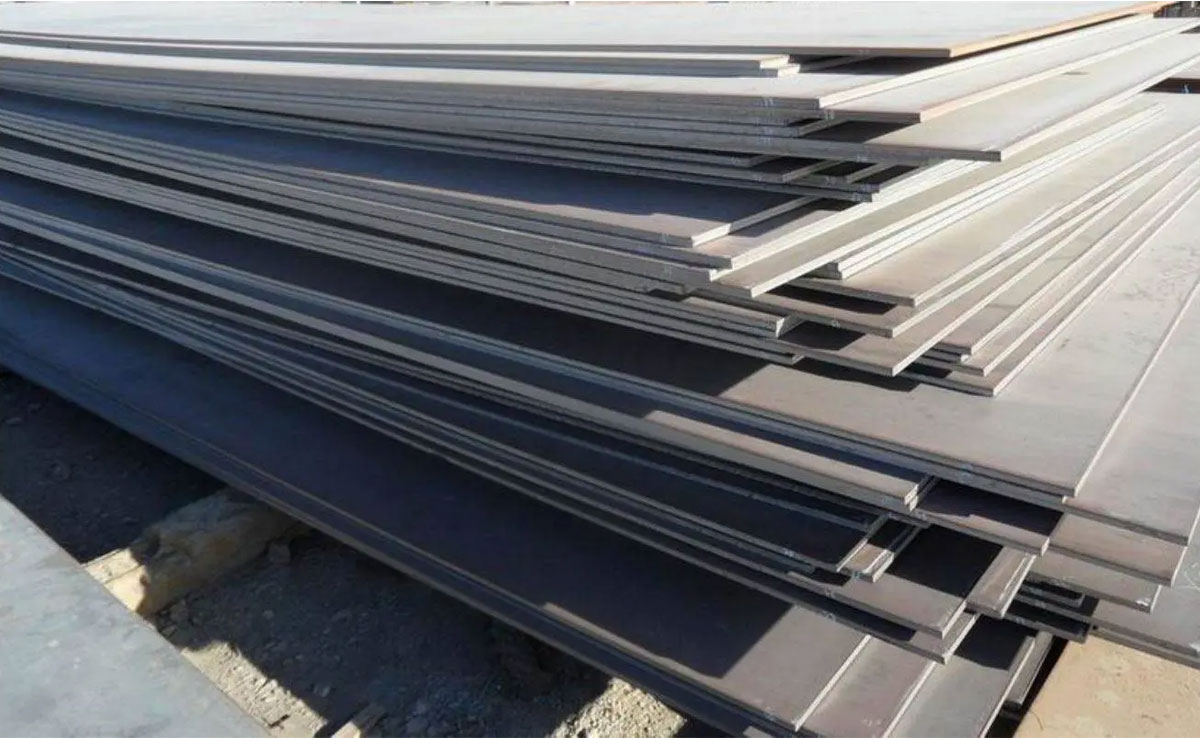

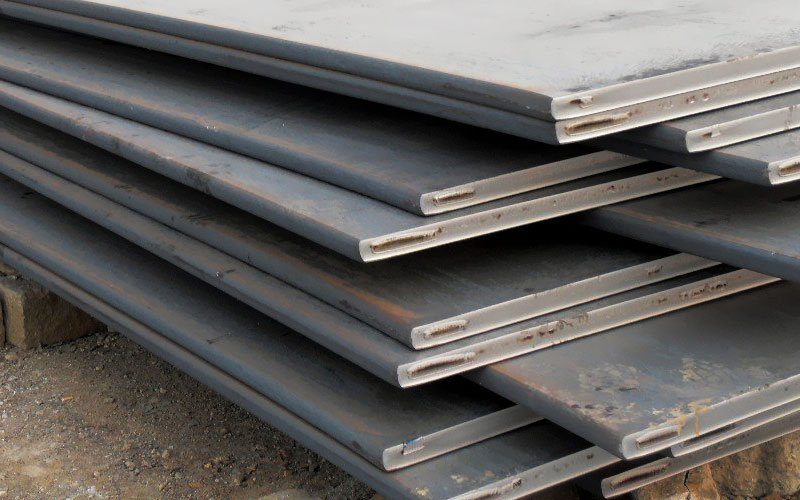

Exploring the Versatility of Mild Steel Plates: A Comprehensive Guide

Introduction:

Mild Steel Plates, commonly known as MS Plates, are a fundamental component in various industries due to their versatility, strength, and durability. In this article, we will delve into the characteristics, applications, and manufacturing processes of MS plates, shedding light on their importance in construction, manufacturing, and beyond.

Understanding Mild Steel:

Mild Steel, also referred to as low carbon steel, is a widely used material due to its excellent mechanical properties and cost-effectiveness. It contains a low carbon content, typically between 0.05% and 0.25%, making it malleable and easy to work with. The addition of small amounts of other elements enhances its strength without compromising its weldability.

Properties of Mild Steel Plates:

Strength and Durability: MS plates are known for their high tensile strength and durability, making them suitable for a wide range of applications in construction and structural engineering.

Weldability: Mild steel plates can be easily welded, making them a preferred choice for manufacturing and fabrication processes. Welding processes such as arc welding and MIG welding are commonly used with MS plates.

Machinability: MS plates are relatively easy to machine, allowing for the fabrication of intricate components and structures.

Applications of MS Plates:

Construction Industry: Mild steel plates are extensively used in the construction of buildings, bridges, and other infrastructure projects. Their strength and durability make them ideal for supporting heavy loads and withstanding structural stress.

Manufacturing and Fabrication: MS plates serve as essential components in the manufacturing and fabrication of machinery, equipment, and various industrial structures. Their versatility allows for the creation of custom-made components to suit specific needs.

Automotive Industry: Mild steel plates find applications in the automotive sector, where they are used to manufacture chassis, body panels, and structural components of vehicles.

Shipbuilding: Due to their strength and corrosion resistance, MS plates are commonly used in the shipbuilding industry for constructing the hulls and structural elements of ships.

Manufacturing Process:

The manufacturing process of MS plates involves several steps, including:

- Iron Ore Mining: The process begins with the extraction of iron ore from mines.

- Smelting: Iron ore is smelted in blast furnaces to produce pig iron.

- Refining: Pig iron is refined to remove impurities and excess carbon.

- Rolling: The refined iron is rolled into thin sheets to produce mild steel plates.

Conclusion:

MS Plates play a pivotal role in various industries, offering a combination of strength, durability, and versatility. From construction to manufacturing, these plates are integral to the development of structures and components that form the backbone of our modern world. Understanding the properties and applications of MS plates is crucial for professionals in diverse fields who rely on the reliability and performance of this essential material.

#msplates, #mildsteelplates, #buymsplatesonline

0 likes · 0 comments

BusinessGautham Shah

2 years ago

Exploring the Advantages of MS Flats in Construction

Introduction:

Mild Steel (MS) flats are widely used in the construction industry for various applications due to their excellent properties and versatility. These flat bars, made from mild steel, have become a popular choice among builders, architects, and engineers. In this blog article, we will delve into the advantages of using MS flats in construction.

Durability and Strength:

MS flats are known for their durability and strength, making them ideal for construction projects. The mild steel composition provides a strong foundation for structures, ensuring longevity and stability. This durability is crucial in withstanding the challenges posed by varying weather conditions and structural loads.

Versatility in Applications:

One of the key advantages of MS flats is their versatility. These flat bars come in various sizes and thicknesses, making them suitable for a wide range of applications. From framing to support structures, MS flats can be used in diverse construction projects, offering flexibility to builders and designers.

Ease of Fabrication:

MS flats are easy to fabricate, cut, and shape according to specific project requirements. This ease of fabrication makes them a preferred choice for construction professionals. Whether it's for creating structural components or adding finishing touches, MS flats allow for precision and customization.

Cost-Effective Solution:

Affordability is a significant factor in construction projects, and MS flats offer a cost-effective solution. Compared to other materials, mild steel is relatively inexpensive, making it a budget-friendly option without compromising on quality and performance.

Resistance to Corrosion:

Mild steel flats are coated with a layer of zinc through galvanization, which provides resistance to corrosion. This makes them suitable for outdoor applications where exposure to moisture and environmental elements is a concern. The protective coating enhances the lifespan of MS flats, reducing the need for frequent replacements.

Recyclability:

As sustainability becomes a focal point in construction practices, MS flats stand out for their recyclability. Mild steel is highly recyclable, making it an eco-friendly choice. Using recycled MS flats in construction contributes to reducing the environmental impact and promoting a circular economy.

Uniform Quality:

MS flats are manufactured with consistent quality standards, ensuring uniformity in strength and dimensions. This uniformity simplifies the construction process, as builders can rely on the predictable performance of MS flats in various applications.

Conclusion:

In conclusion, MS flats offer a multitude of advantages in construction, ranging from durability and versatility to cost-effectiveness and recyclability. As the construction industry continues to evolve, the use of mild steel flats is likely to persist as an integral component in building robust and sustainable structures. Whether in residential, commercial, or industrial projects, the benefits of MS flats contribute to their popularity and widespread adoption in the construction sector.

0 likes · 0 comments

BusinessGautham Shah

2 years ago

Navigating the Dynamics of JSW Steel Prices: An In-Depth Analysis

Introduction:

In the intricate web of global industries, steel holds a pivotal role, serving as the backbone for infrastructure, construction, and manufacturing. Among the key players in the steel market, JSW Steel stands out as a prominent force, known for its innovation, sustainability initiatives, and commitment to quality. In this blog article, we will delve into the dynamics of JSW Steel prices, exploring the factors influencing them and their broader implications on the industry.

Understanding JSW Steel:

JSW Steel, part of the JSW Group, is one of India's leading integrated steel manufacturers with a significant global presence. The company has a diversified product portfolio, encompassing a range of flat and long steel products, catering to various industries such as automotive, construction, infrastructure, and appliances.

Factors Influencing JSW Steel Prices:

- Raw Material Costs:

One of the primary factors affecting steel prices is the cost of raw materials, particularly iron ore and coking coal. Fluctuations in these input costs can have a direct impact on the overall production cost of steel.

- Global Economic Trends:

Steel demand is closely tied to the economic health of nations. Global economic trends, such as GDP growth, infrastructure development, and manufacturing output, play a crucial role in determining the demand for steel products, thereby influencing prices.

- Government Policies and Trade Tariffs:

Trade policies, tariffs, and government regulations can significantly impact the steel industry. Changes in these policies, especially those related to imports and exports, can affect the supply-demand dynamics and consequently influence steel prices.

- Technological Advances and Innovation:

JSW Steel is known for its emphasis on technological innovation. The adoption of advanced manufacturing processes and technologies can enhance efficiency, reduce costs, and potentially influence pricing strategies.

- Environmental Regulations:

Increasing global awareness of environmental sustainability has led to stricter regulations on emissions and waste disposal in the steel industry. Compliance with these regulations may necessitate investments in cleaner technologies, potentially impacting production costs and prices.

- Currency Fluctuations:

As a global player, JSW Steel is exposed to currency fluctuations. Changes in exchange rates can affect the cost of imported raw materials and impact the competitiveness of the company in the international market.

Implications for Stakeholders:

- Construction and Infrastructure:

Fluctuations in JSW Steel prices can impact the cost of construction and infrastructure projects, potentially influencing the pace of development and investment decisions.

- Automotive Industry:

The automotive sector, a significant consumer of steel, is sensitive to price changes. Automakers may adjust production and pricing strategies based on steel price trends.

- Investors:

Investors closely monitor steel prices as part of their risk assessment for companies in the steel sector. Understanding the factors influencing JSW Steel prices is crucial for making informed investment decisions.

Conclusion:

The dynamics of JSW Steel prices are multifaceted, shaped by global economic trends, technological advancements, and regulatory changes. As a key player in the steel industry, JSW Steel's pricing strategies and market performance have far-reaching implications for various stakeholders. Keeping a watchful eye on these factors is essential for understanding the broader landscape of the steel market and its role in shaping the industrial and economic landscape.

0 likes · 0 comments

BusinessDo you want to manage your own group?