Geeta Swamy

Hyderabad, Hyderabad

Geeta Swamy

1 year ago

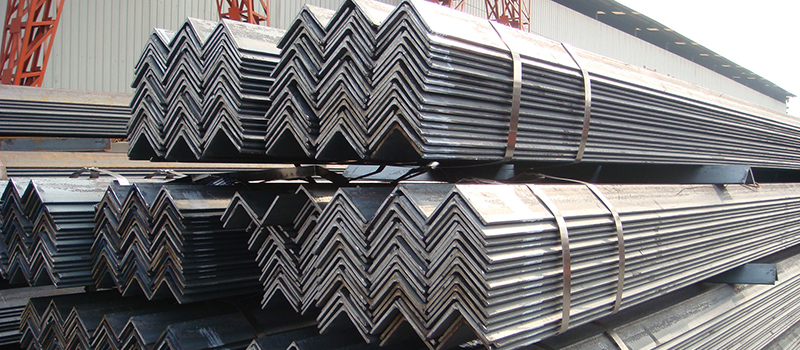

Building Strong Foundations: The Role of Mild Steel Angles in Construction

Mild steel angles are ubiquitous in the realm of construction, filling in as essential structural parts in a myriad of undertakings. From residential buildings to industrial complexes, these angles play a pivotal role in providing strength, stability, and versatility to various structures. In this article, we dive into the characteristics, applications, and advantages of mild steel angles in construction.

Characteristics of Mild Steel Angles

Mild steel, also known as low carbon steel, is a popular decision for structural applications because of its favorable combination of strength, flexibility, and affordability. Mild steel angles are typically framed by bowing a solitary piece of mild steel into a L-shaped cross-segment. These angles are characterized by their equal-length legs joined at a right angle, making them suitable for load-bearing applications.

One of the primary characteristics of mild steel angles is their high rigidity, which enables them to withstand substantial loads without disfiguring or failing. Additionally, mild steel angles display brilliant weldability, allowing for easy fabrication and customization to meet explicit undertaking necessities. Moreover, their consumption resistance can be enhanced through various surface treatments, making them suitable for both indoor and outdoor applications.

Applications of Mild Steel Angles

The versatility of mild steel angles fits an extensive variety of construction applications across various businesses. A few normal purposes of mild steel angles include:

Structural Support: Mild steel angles are regularly utilized as structural support parts in buildings and infrastructure projects. They give essential support to beams, sections, and frames, adding to the overall stability and honesty of the construction.

Framing and Bracing: In residential and commercial construction, mild steel angles are used for framing and bracing purposes. They are utilized in wall framing, roof trusses, and floor joists to create vigorous frameworks that can withstand vertical and lateral loads.

Staircases and Handrails: Mild steel angles are often incorporated into staircase construction, filling in as stringers, treads, and handrail supports. Their durability and stylish appeal make them a popular decision for both inside and outside staircases in residential and commercial buildings.

Industrial Equipment: In industrial settings, mild steel angles track down application in the fabrication of machinery, equipment, and support structures. They are utilized in transport frameworks, storage racks, and platform constructions because of their strength and unbending nature.

Architectural Detailing: Mild steel angles are also valued for their tasteful versatility in architectural detailing. They can be utilized to create decorative accents, such as trim, moldings, and ornamental features, adding visual interest to building facades and interiors.

Advantages of Mild Steel Angles

The widespread adoption of mild steel angles in construction can be attributed to several key advantages:

Cost-Effectiveness: Mild steel is an economical material decision compared to alternatives such as stainless steel or aluminum. Its affordability makes mild steel angles a cost-compelling answer for construction projects without settling for less on quality or performance.

Strength and Durability: Mild steel angles offer high rigidity and durability, guaranteeing long haul structural honesty and resistance to deformation under heavy loads. This strength-to-weight ratio makes them suitable for demanding applications where heartiness is essential.

Ease of Fabrication: Mild steel angles are easily fabricated, allowing for effective customization and adaptation to explicit task necessities. They can be cut, welded, penetrated, and framed effortlessly, enabling fast and exact construction processes.

Versatility: Mild steel angles are available in a large number of sizes, thicknesses, and configurations, making them versatile for various construction applications. Whether utilized for structural support or decorative detailing, mild steel angles offer adaptability in plan and implementation.

Recyclability: Mild steel is an exceptionally recyclable material, adding to sustainability endeavors in the construction business. At the finish of its administration life, mild steel angles can be reused and reused, lessening environmental impact and rationing natural assets.

In conclusion, mild steel angles are indispensable parts in modern construction, offering a unique combination of strength, versatility, and cost-effectiveness. From structural support to architectural detailing, these angles play a crucial role in shaping the fabricated climate. With their various advantages and widespread applications, mild steel angles keep on being a favored decision for specialists, architects, and developers around the world.

#ms angles #Steel Products #Real Estate Developers

0 likes · 0 comments

Science and TechnologyGeeta Swamy

1 year ago

Interpreting the Elements of Iron Price Per Kilogram: Factors, Trends, and Suggestions

In the domain of economics and industry, the price of iron per kg holds huge significance, filling in as a gauge for different areas going from development and assembling to foundation improvement and transportation. Understanding the complex factors influencing iron prices, following recent trends, and investigating the more extensive ramifications for various enterprises is significant for stakeholders across the economic spectrum. In this article, we dig into the complexities of iron per kg price, taking apart its fundamental factors, examining recent trends, and assessing its suggestions on assorted enterprises.

Factors Influencing Iron Price Per kg

- Worldwide Demand and Supply: The key guideline of the organic market assumes a critical part in deciding iron prices. Variances in worldwide demand for iron, driven by economic development, framework improvement, and assembling exercises, can impact market prices. Essentially, changes in the worldwide stock of iron because of changes in mining yield, creation limits, and exchange elements influence price elements.

- Unrefined substance Costs: The cost of iron creation is straightforwardly affected by the prices of its essential natural substances, quite iron mineral and salvaged material. Variances in worldwide iron mineral prices, driven by factors like mining guidelines, international strains, and changes in demand from key consuming businesses, can affect the cost of iron creation and, thus, its market price.

- Energy Prices: Iron creation is energy-serious, with critical power and fuel utilization engaged with cycles like mining, purifying, and refining. Variances in energy prices, affected by factors like international pressures, administrative changes, and mechanical progressions in environmentally friendly power, can straightforwardly influence the iron per kg price.

- Market Hypothesis and Financial backer Opinion: Market theory, financial backer feeling, and macroeconomic factors, for example, loan costs, expansion, and cash vacillations can impact iron prices. Speculative exchanging exercises ware markets, international vulnerabilities, and changes in financial backer gamble craving can prompt price unpredictability and transient variances in iron prices.

- Money Trade Rates: Iron prices are likewise impacted by cash trade rates, especially for nations that are significant makers or buyers of iron. Changes in return rates influence the cost of bringing in or sending out iron, influencing market prices and exchange elements.

Recent Trends in Iron Price Per kg

In recent years, a few trends have arisen that have impacted the elements of iron per kg price:

- Unpredictability in Unrefined substance Prices: Vacillations in worldwide iron metal prices, driven by factors, for example, supply disturbances, changes in demand from significant customers like China, and international strains, have prompted unpredictability in the cost of iron creation and market prices.

- Worldwide Economic Circumstances: Economic trends, including Gross domestic product development, modern result, and framework spending, impact the demand for iron and steel items, accordingly affecting business sector prices. Economic slumps or lulls can prompt discounted demand and a descending strain on iron prices.

- Framework and Development Action: The degree of foundation improvement and development action in key areas like China, India, and the US fundamentally impacts the demand for iron and steel items, influencing market prices. Enormous scope foundation activities and urbanization drive demand for iron in areas like transportation, lodging, and utilities.

- Environmental Guidelines and Manageability Drives: Developing worries about environmental supportability have prompted expanded administrative investigation and maintainability drives inside the iron and steel industry. Interests in cleaner creation advances, energy effectiveness measures, and fossil fuel byproduct decrease strategies add to creation costs and can affect market prices.

Suggestions for Different Ventures

- Development and Framework: Iron price per kg straightforwardly influences development and foundation projects, as iron and steel are major materials utilized in structures, scaffolds, streets, and different designs. Vacillations in iron prices can impact project financial plans, development timetables, and foundation improvement plans.

- Fabricating and Auto: Iron and steel are imperative contributions to assembling processes, especially in businesses, for example, car, hardware, and apparatuses. Changes in iron prices can influence fabricating costs, item evaluating strategies, and store network elements in these areas.

- Energy and Utilities: The energy-escalated nature of iron creation implies that variances in energy prices can fundamentally affect the iron per kg price. Energy and utilities organizations, incorporating those engaged with power age and fuel supply, are impacted by changes in iron creation costs, especially in locales where iron creation is a critical consumer of energy.

- Venture and Monetary Business sectors: Iron prices and creation costs can likewise impact speculation choices and monetary business sectors. Financial backers in mining organizations, steel makers, and related enterprises intently screen iron price trends and creation cost elements to survey venture open doors and oversee portfolio risk.

Conclusion

The iron per kg price is impacted by a complicated interchange of factors, including worldwide demand and supply elements, unrefined substance costs, energy prices, market hypothesis, and macroeconomic trends. Recent trends like unpredictability in natural substance prices, worldwide economic circumstances, foundation and development action, and environmental guidelines have huge ramifications for businesses dependent on iron and steel items. Understanding these price elements is fundamental for stakeholders across different areas, empowering informed direction, strategic preparation, and hazarding the executives in a dynamic and developing commercial center.

0 likes · 0 comments

Science and TechnologyGeeta Swamy

1 year ago

Exploring the Utility of MS Channels: A Comprehensive Outline

In the domain of construction, infrastructure, and manufacturing, materials that offer robustness, versatility, and usability are highly valued. Mild Steel (MS) channels, also known as C-channels or U-channels, stand out as essential components in various industries due to their structural strength and adaptability. In this comprehensive outline, we delve into the characteristics, manufacturing process, applications, and advantages of MS channels, shedding light on their versatile role in assorted sectors.

Understanding MS Channels

MS channels are structural steel components characterized by their C-shaped or U-shaped cross-section. They feature a web with two flanges on one or the other side, providing structural support and load-bearing capabilities in various applications. MS channels are typically produced using mild steel, a low-carbon steel variation known for its versatility, weldability, and cost-effectiveness. They come in various sizes, thicknesses, and lengths to suit different structural and engineering requirements.

Manufacturing Process

The manufacturing process of MS channels involves several phases, including:

- Steel Billet Production: The process begins with the production of steel billets through essential steelmaking processes such as basic oxygen furnace (BOF) or electric arc furnace (EAF). These billets act as unrefined substances for the production of MS channels.

- Rolling Mill: The steel billets are warmed and gone through a progression of rolling mills to form the ideal cross-sectional shape. In the case of MS channels, the billets are rolled into C-shaped or U-shaped profiles with a web and two flanges.

- Cutting and Finishing: After the rolling process, the MS channels are cut to the required lengths and subjected to finishing processes such as straightening, surface treatment, and inspection to ensure dimensional accuracy and surface quality.

Key Characteristics of MS Channels

- Structural Strength: MS channels offer high structural strength, making them suitable for load-bearing applications in construction, infrastructure, and manufacturing.

- Versatility: MS channels are versatile structural components used in a large number of applications, including building frames, supports, bracing, and reinforcements.

- Simplicity of Fabrication: MS channels are not difficult to fabricate, cut, weld, and manipulate using common fabrication techniques such as cutting, drilling, welding, and bending, allowing for simple customization and assembly in various projects.

- Cost-Effectiveness: MS channels are cost-effective structural steel components compared to different materials, making them a favored choice for construction and they are paramount to engineer projects where cost considerations.

Applications of MS Channels

- Construction and Building Structures: MS channels find broad use in the construction industry for building frames, roof trusses, supports, columns, and bracing elements. They give structural stability and support in residential, commercial, and industrial buildings.

- Infrastructure and Engineering Projects: MS channels play a vital role in infrastructure projects such as scaffolds, flyovers, dams, and transmission towers. They offer structural help and reinforcement in civil engineering projects requiring load-bearing structures.

- Manufacturing and Industrial Applications: MS channels are used in manufacturing and industrial applications for producing machinery frames, equipment supports, conveyor systems, and storage racks. They act as structural components in various industrial applications where strength and stability are required.

- Marine and Offshore Structures: MS channels are also used in marine and offshore structures such as shipbuilding, offshore platforms, and port facilities. They offer structural help and reinforcement in sea conditions where corrosion resistance and durability are essential.

Advantages of MS Channels

- Structural Strength: MS channels offer high structural strength, providing reliable support and stability in various applications.

- Versatility: MS channels are versatile components used in a great many applications across industries, from construction and infrastructure to manufacturing and marine engineering.

- Simplicity of Fabrication: MS channels are not difficult to fabricate, cut, weld, and manipulate using common fabrication techniques, allowing for simple customization and assembly in different projects.

- Cost-Effectiveness: MS channels are cost-effective structural steel components compared to different materials, making them an economical choice for construction and engineering projects.

Conclusion

MS channels, with their structural strength, versatility, simplicity of fabrication, and cost-effectiveness, are indispensable components in construction, infrastructure, manufacturing, and marine engineering projects. From building frames and supports to infrastructure projects and industrial applications, MS channels play a vital role in providing structural stability, support, and reinforcement in different applications. As industries continue to prioritize efficiency, durability, and cost-effectiveness, the demand for MS channels is expected to be major areas of strength for remain, innovation and advancements in structural steel fabrication for years to come.

0 likes · 0 comments

BusinessGeeta Swamy

2 years ago

Unveiling the Today's Tata Tiscon Price List: Insights and Examination

Tata Tiscon, a trusted name in the steel industry, is famous for its great construction and reinforcement bars that set the standard for strength and durability. As a leading supplier of steel arrangements, Tata Tiscon price list today is a key reference point for stakeholders in the construction area, offering insights into market patterns, pricing dynamics, and material costs. In this article, we dig into the ongoing Tata Tiscon price list, dissect its implications, and give significant insights to industry professionals and consumers.

Understanding Tata Tiscon Price List

The Tata Tiscon price list today fills in as a far reaching reference guide for the pricing of Tata Tiscon reinforcement bars across different particulars and grades. Refreshed consistently to reflect market dynamics and changes in material costs, the price list gives transparency and lucidity to stakeholders, including construction companies, contractors, architects, and individual consumers.

Factors Influencing Tata Tiscon Prices

The pricing of Tata Tiscon reinforcement bars is influenced by a large number of factors, including:

Raw Material Costs: The essential raw materials utilized in the development of Tata Tiscon bars, like iron metal, coal, and alloying components, straightforwardly influence material costs. Fluctuations in raw material prices, driven by supply-demand dynamics, geopolitical factors, and environmental regulations, influence Tata Tiscon prices.

Manufacturing Costs: Creation costs, including energy costs, work expenses, and overheads, add to the general cost design of Tata Tiscon bars. Effectiveness enhancements, innovative progressions, and functional advancements can influence manufacturing costs and, along these lines, item pricing.

Market Demand and Supply: Market demand for Tata Tiscon bars, influenced by construction movement, infrastructure investments, and industrial activities, influences pricing choices. Supply-demand irregular characteristics, creation limits, and inventory levels likewise influence market dynamics and pricing strategies.

Currency Fluctuations: Tata Tiscon prices might be influenced by currency conversion scale fluctuations, especially for imported raw materials and gear. Changes in return rates comparative with the Indian rupee can influence material costs and, subsequently, item pricing.

Government Policies: Government policies, including expenses, obligations, and regulations connected with the steel industry, can influence Tata Tiscon prices. Changes in tax collection, import-send out policies, and environmental regulations might influence creation costs and pricing strategies.

Implications of Tata Tiscon Price List Today

The Tata Tiscon price list has a few implications for stakeholders in the construction area:

Cost Estimation: Construction companies, contractors, and project administrators depend on the Tata Tiscon price list for accurate cost estimation and budgeting. The price list empowers them to design and execute construction projects actually by incorporating material costs into project financial plans.

Procurement Planning: Manufacturers and designers utilize the Tata Tiscon price list to design their procurement exercises and advance material sourcing. By monitoring price patterns and fluctuations, they can settle on informed choices regarding the timing and amount of Tata Tiscon bars procurement.

Consumer Awareness: Individual consumers, including mortgage holders and limited scope developers, reference the Tata Tiscon price list to understand the cost implications of using Tata Tiscon bars in their construction projects. The price list gives transparency and empowers consumers to go with informed choices in light of their spending plan and undertaking necessities.

Competitive Pricing: Tata Tiscon dealers and merchants utilize the price list to set competitive pricing strategies and remain competitive in the market. By aligning their pricing with market patterns and client inclinations, they can draw in clients and maintain market share.

Industry Benchmarking: The Tata Tiscon price list fills in as a benchmark for comparing prices and evaluating competitiveness within the steel industry. Contenders and industry experts utilize the price list to evaluate market positioning, pricing strategies, and pricing patterns.

Conclusion

In conclusion, the Tata Tiscon price list assumes a fundamental part in the construction area, providing stakeholders with significant insights into market patterns, pricing dynamics, and material costs. By understanding the factors influencing Tata Tiscon prices and analyzing the implications of the price list, industry professionals and consumers can pursue informed choices regarding procurement, budgeting, and project planning. As a trusted reference point for steel prices, the Tata Tiscon price list today continues to be a significant asset for the construction industry, enabling stakeholders to explore market uncertainties and enhance their business strategies.

0 likes · 0 comments

BusinessGeeta Swamy

2 years ago

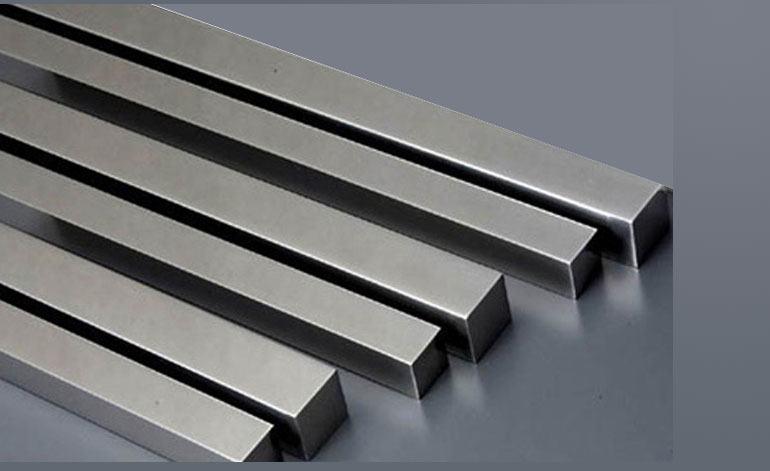

Investigating the Adaptability of MS Squares: Applications, Benefits, and Market Trends

Mild Steel (MS) squares, otherwise called mild steel square bars or square poles, are adaptable metal parts broadly used across different industries for their primary respectability, durability, and simplicity of manufacture. In this article, we dive into the qualities, applications, benefits, and market trends of MS squares.

Qualities of MS Squares

MS squares are produced from low carbon steel, regularly containing under 0.25% carbon, which gives beneficial properties like malleability, weldability, and machinability. They are accessible in different aspects, going from little measured squares utilized in family applications to bigger segments utilized in modern settings.

The microstructure of MS squares principally comprises ferrite and pearlite stages, adding to their mechanical properties. These squares are commonly delivered through hot rolling or cold drawing processes, bringing about uniform aspects and surface completion.

Applications of MS Squares

MS squares track down boundless applications across assorted industries because of their flexibility, primary strength, and simplicity of creation. A few normal applications include:

- Construction: MS squares are broadly utilized in construction projects for creating support structures, casings, sections, and reinforcements. Their vigor and burden bearing limit make them ideal for building frameworks, flights of stairs, railings, and design components.

- Manufacturing and Designing: In manufacturing and designing sectors, MS squares are utilized in hardware parts, gear outlines, tooling, and dances. Their machinability considers simple cutting, boring, and molding to meet explicit plan prerequisites.

- Creation and Welding: MS squares are liked in manufacture and welding applications because of their weldability and formability. They are utilized in the manufacture of doors, walls, grilles, and other metal designs requiring exact welding and gathering.

- Furniture and Inside Plan: MS squares are used in the creation of furniture outlines, racking units, table legs, and ornamental components in inside plan. Their perfect lines, uniform aspects, and primary strength make them reasonable for current and modern style furniture plans.

- Automotive and Transportation: MS squares track down applications in automotive and transportation industries for creating skeleton parts, edges, sections, and primary reinforcements. Their strength-to-weight proportion and primary respectability add to the durability and wellbeing of vehicles and transportation hardware.

Benefits of MS Squares

MS squares offer a few benefits over other materials, adding to their broad reception across industries:

- Cost-Adequacy: MS squares are practical contrasted with other metals, settling on them an economical decision for different applications without settling on quality or performance.

- Flexibility: MS squares can be effortlessly manufactured, welded, and machined to meet explicit plan prerequisites, making them reasonable for a large number of applications across industries.

- Strength and Durability: MS squares display amazing strength and durability, making them ideal for primary applications where load-bearing limit and flexibility are fundamental.

- Simplicity of Support: MS squares require negligible upkeep and can withstand unforgiving natural circumstances, making them reasonable for open air and modern applications.

- Recyclability: MS squares are recyclable, adding to manageability drives and diminishing ecological effect through the reuse of materials.

Market Trends in MS Squares

The market for MS squares is affected by different factors, including modern demand, raw material costs, mechanical headways, and regulatory strategies. A few prominent trends molding the MS squares market include:

- Modern Demand: The demand for MS squares is driven by modern exercises, infrastructure improvement, and construction projects. Variances in global economic circumstances and government interests in infrastructure influence the demand for MS squares.

- Mechanical Progressions: Advances in steel manufacturing advancements add to the development of top notch MS squares with worked on mechanical properties and surface completion. Makers are embracing progressed creation methods to fulfill the developing need for accuracy designed MS squares.

- Natural Guidelines: Severe ecological guidelines in regards to emanations decrease and manageability drive the reception of cleaner creation processes in the steel business. Producers of MS squares are progressively zeroing in on earth maintainable practices and materials.

- Customization and Worth Added Administrations: Producers of MS squares are offering customized arrangements and worth added administrations like cutting, boring, and surface treatment to meet the particular prerequisites of end-clients across industries.

- Market Contest: The MS squares market is portrayed by extreme rivalry among makers, both locally and globally. Organizations are zeroing in on item separation, development, and customer administration to acquire an upper hand on the lookout.

Conclusion

MS squares are fundamental primary parts used across different industries for their adaptability, strength, and cost-adequacy. With their colossal applications in construction, manufacturing, creation, and designing, MS squares assume a pivotal part in current infrastructure and modern turn of events.

As the global economy keeps on developing, the demand for MS squares is supposed to stay powerful, determined by infrastructure ventures, modern extension, and mechanical headways. Makers and partners in the MS squares market should adjust to changing business sector dynamics, mechanical developments, and regulatory necessities to support development and stay cutthroat in the business.

0 likes · 0 comments

BusinessDo you want to manage your own group?