Lilly Singh

Visakhapatnam, Visakhapatanam

Lilly Singh

1 year ago

Unlocking the Versatility of Mild Steel Sheets: Advantages and Applications

Mild steel, otherwise called low carbon steel, is perhaps the most broadly involved material in different enterprises due to its remarkable properties and affordability. Mild steel sheets, specifically, offer plenty of advantages and find applications in different sectors going from construction to automotive manufacturing. We should dig further into the advantages and applications of mild steel sheets.

Advantages of Mild Steel Sheets:

Cost-Effective: Mild steel sheets are profoundly cost-effective contrasted with different materials like hardened steel or aluminum. This affordability settles on them a favored decision for enormous scope projects where cost productivity is pivotal.

Malleability: Mild steel sheets are pliant and can be effectively framed into different shapes and sizes without undermining their primary respectability. This property makes them ideal for applications where complex plans or customized shapes are required.

Weldability: Mild steel sheets display phenomenal weldability, taking into consideration simple getting together with different parts or designs utilizing different welding procedures. This trademark improves their versatility and makes them reasonable for an extensive variety of fabrication processes.

Strength and Durability: Notwithstanding being named "mild," mild steel sheets offer impressive strength and durability, making them reasonable for demanding applications. They can withstand weighty burdens and outer powers, guaranteeing long haul primary honesty in assorted conditions.

Corrosion Resistance: While not quite as corrosion-safe as tempered steel, mild steel sheets can in any case withstand moderate openness to dampness and climatic circumstances. Legitimate surface treatment or covering can improve their corrosion resistance, making them appropriate for open air applications.

Recyclability: Mild steel is profoundly recyclable, adding to natural supportability and lessening the general carbon impression of manufacturing processes. This eco-accommodating trademark lines up with the developing accentuation on supportable practices across ventures.

Applications of Mild Steel Sheets:

Construction: Mild steel sheets track down broad applications in the construction business for manufacturing underlying parts, like pillars, sections, and roofing boards. Their strength, durability, and affordability make them imperative for both private and business construction projects.

Automotive Manufacturing: Mild steel sheets are broadly utilized in the automotive sector for manufacturing different parts, including frame, body boards, and primary fortifications. Their mix of strength, formability, and cost-effectiveness makes them ideal for large scale manufacturing in the automotive business.

Machinery and Equipment: Mild steel sheets assume a significant part in the fabrication of machinery and equipment across various ventures. From manufacturing transport lines to farming machinery parts, their versatility takes care of many industrial applications.

Shipbuilding: Mild steel sheets are used in the shipbuilding business for building frames, bulkheads, and other primary elements of boats and offshore stages. Their capacity to withstand unforgiving marine conditions pursues them as a favored decision for oceanic applications.

Storage Tanks and Containers: Mild steel sheets are usually utilized in the fabrication of storage tanks, containers, and storehouses for storing different substances like liquids, gases, and granular materials. Their strength and weldability guarantee the underlying honesty of storage arrangements in industrial settings.

Furniture and Decorative Items: Mild steel sheets are likewise utilized in the manufacturing of furniture, decorative items, and architectural elements due to their tasteful appeal, formability, and ease of fabrication. From contemporary furniture plans to mind boggling metal craftsmanship, mild steel sheets offer vast opportunities for innovative articulation.

Infrastructure and Utilities: Mild steel sheets are fundamental for infrastructure improvement projects, including scaffolds, pipelines, and utility designs. Their dependability and cost-effectiveness make them crucial for building versatile infrastructure to help developing metropolitan populaces.

In conclusion, mild steel sheets are irreplaceable materials that offer an ideal mix of strength, versatility, and affordability. Their advantages, including cost-effectiveness, malleability, weldability, and durability, make them profoundly pursued in different ventures like construction, automotive manufacturing, machinery fabrication, shipbuilding, and more. From primary parts to decorative items, mild steel sheets keep on molding present day enterprises and infrastructure, driving advancement and progress across assorted sectors.

0 likes · 0 comments

BusinessLilly Singh

1 year ago

Deciphering the Elements of Iron Cost Per Kilogram: Factors, Trends, and Implications

Iron, quite possibly the most bountiful and fundamental metal on the planet, fills in as a foundation in various industries, from development and manufacturing to transportation and infrastructure improvement. Understanding the cost elements of iron per kilogram is pivotal for stakeholders across these areas, as it straightforwardly influences creation costs, pricing systems, and investment choices. In this article, we dig into the multi-layered factors influencing the iron cost per kg, examine recent trends, and investigate the more extensive implications for different industries.

Factors Influencing Iron Cost Per Kilogram

- Raw Material Prices: The cost of iron is intricately linked to the prices of its essential raw materials, strikingly iron mineral and salvaged material. Fluctuations in global demand and supply, geopolitical factors, and mining regulations can altogether influence the prices of these raw materials, accordingly impacting the general cost of iron creation.

- Energy Costs: Iron creation is energy-intensive, with critical power and fuel utilization involved in cycles like mining, smelting, and refining. Fluctuations in energy prices, driven by factors like geopolitical tensions, regulatory changes, and technological progressions in sustainable power, can straightforwardly influence the cost of iron creation per kilogram.

- Labor Costs: The labor-intensive nature of certain iron creation processes, like mining and smelting, makes labor costs a critical part of the general cost per kilogram. Factors, for example, wage inflation, labor market conditions, and labor efficiency upgrades can influence labor costs and, consequently, the cost of iron creation.

- Technological Advances: Technological innovations assume an essential part in shaping the cost elements of iron creation. Headways in mining advances, smelting cycles, and proficiency enhancements in steelmaking can prompt cost decreases per kilogram of iron delivered, along these lines influencing market prices.

- Regulatory Environment: Environmental regulations, wellbeing standards, and consistency necessities forced by legislatures and international bodies can affect the cost of iron creation. Investments in contamination control measures, adherence to discharge standards, and consistency with labor regulations can add to creation costs and influence the cost per kilogram of iron.

Recent Trends in Iron Cost Per Kilogram

In recent years, a few trends have arisen that have influenced the cost elements of iron cost per kg:

- Volatility in Raw Material Prices: Fluctuations in global iron mineral and salvaged material prices have added to volatility in the cost of iron creation. Factors, for example, exchange tensions, supply chain disturbances, and changes in demand from key consuming industries have prompted cost fluctuations, impacting the cost per kilogram of iron.

- Environmental Regulations and Sustainability Initiatives: Growing worries about environmental sustainability have prompted increased regulatory scrutiny and sustainability initiatives within the iron and steel industry. Investments in cleaner creation advances, energy productivity measures, and fossil fuel byproduct decrease methodologies have added to creation costs yet are pointed toward improving long haul sustainability.

- Technological Innovations: The reception of trend setting innovations, like robotization, man-made consciousness, and digitalization, has prompted productivity upgrades and cost decreases in certain fragments of the iron creation process. These technological headways have added to optimizing operations and lowering the cost per kilogram of iron created.

- Global Economic Conditions: Economic trends and macroeconomic factors, like Gross domestic product development, industrial result, and infrastructure spending, influence the demand for iron and steel items, accordingly impacting market prices. Economic slumps or lulls can prompt discounted demand and a descending strain on iron prices, affecting the cost per kilogram.

Implications for Different Industries

- Development and Infrastructure: The cost of iron per kilogram straightforwardly influences development and infrastructure projects, as iron and steel are essential materials utilized in buildings, scaffolds, streets, and different designs. Fluctuations in iron prices can influence project spending plans, development timelines, and infrastructure improvement plans.

- Manufacturing and Car: Iron and steel are crucial inputs in manufacturing processes, especially in industries, for example, auto, machinery, and apparatuses. Changes in iron prices can influence manufacturing costs, item pricing procedures, and supply chain elements in these areas.

- Energy and Utilities: The energy-intensive nature of iron creation implies that fluctuations in energy prices can altogether affect the iron cost per kg. Energy and utilities organizations, including those involved in power age and fuel supply, are influenced by changes in iron creation costs, especially in districts where iron creation is a huge buyer of energy.

- Investment and Financial Markets: Iron prices and creation costs can likewise influence investment choices and financial markets. Investors in mining organizations, steel makers, and related industries intently screen iron value trends and creation cost elements to survey investment open doors and oversee portfolio risk.

Conclusion

The iron cost per kg is molded by an intricate interplay of factors, including raw material prices, energy costs, labor costs, technological headways, and regulatory contemplations. Recent trends like volatility in raw material prices, environmental regulations, technological innovations, and global economic conditions have huge implications for industries dependent on iron and steel items. Understanding these cost elements is fundamental for stakeholders across different areas, enabling informed navigation, vital planning, and chance administration in a dynamic and evolving marketplace.

0 likes · 0 comments

BusinessLilly Singh

1 year ago

Steel Baddi: A Versatile Product Driving Industrial Growth

Introduction

In the domain of industrial products, Steel Baddi stands out as a versatile and fundamental material that drives growth across different sectors. Prestigious for its strength, durability, and adaptability, Steel Baddi has turned into a cornerstone in construction, manufacturing, and infrastructure development. This article explores the meaning of Steel Baddi as a product, its applications, manufacturing process, and its part in encouraging industrial growth.

Versatility and Applications

Steel Baddi, a product made from excellent steel composites, tracks down broad applications across different industries. In construction, it fills in as an essential part in the fabrication of beams, columns, and structural elements, providing structural integrity to buildings, bridges, and infrastructure projects. Moreover, Steel Baddi is fundamental in manufacturing machinery, equipment, and automotive components, where its strength and malleability are crucial for ensuring performance and longevity.

Manufacturing Process

The manufacturing process of Steel Baddi includes a progression of complicated advances pointed toward accomplishing wanted properties and particulars. It normally starts with the determination of raw materials, including iron ore, coal, and alloying elements such as chromium, nickel, and manganese. These materials are then softened in electric circular segment heaters or blast heaters, where they go through refining and alloying processes to achieve the ideal arrangement and metallurgical properties.

When dissolved and refined, the liquid steel is cast into different shapes such as billets, blooms, or slabs through constant casting or ingot casting strategies. These semi-completed products are then exposed to additional processing, including rolling, forging, and intensity therapy, to accomplish the ideal aspects, mechanical properties, and surface completion. At last, the completed Steel Baddi products go through quality control measures to guarantee consistent with industry standards and customer details.

Industrial Growth Driver

Steel Baddi assumes a significant part as a driver of industrial growth, adding to the extension and development of key sectors inside the economy. In the construction business, Steel Baddi empowers the construction of strong and supportable infrastructure, including skyscrapers, bridges, and transportation networks, subsequently encouraging metropolitan development and economic advancement. Moreover, in the manufacturing sector, Steel Baddi fills in as a major material for creating machinery, equipment, and consumer goods, supporting industrialization and technological advancement.

Furthermore, the production and utilization of Steel Baddi animate economic action along the inventory network, setting out business open doors, and creating incomes for raw material providers, makers, and distributors. Its versatility and inescapable use additionally add to the growth of subordinate industries such as fabrication, welding, and metalworking, further enhancing its effect on industrial growth and development.

Future Outlook and Innovations

Looking forward, the future outlook for Steel Baddi stays hopeful, driven by advancements in manufacturing advances, developing infrastructure ventures, and advancing business sector demands. Innovations in steelmaking processes, including the reception of electric circular segment heaters, persistent casting advancements, and reusing drives, are supposed to improve productivity, lessen environmental effect, and streamline production costs.

Moreover, the rising emphasis on feasible development and eco-accommodating practices is driving innovations in steel production, prompting the development of high-strength, lightweight steel amalgams with further developed performance attributes. These innovations are ready to open new opportunities for Steel Baddi applications in sectors such as sustainable power, electric versatility, and high level manufacturing, preparing to proceed with industrial growth and thriving.

Conclusion

In conclusion, Steel Baddi stands as a versatile and vital product that drives industrial growth, encourages economic development, and empowers development across different sectors. Its strength, durability, and adaptability go with it a favored decision in construction, manufacturing, and infrastructure projects, molding the landscape of current industries and adding to cultural advancement. As technological advancements and market elements keep on developing, Steel Baddi stays ready to assume a vital part in molding the future of industrialization and economic growth.

0 likes · 0 comments

BusinessLilly Singh

2 years ago

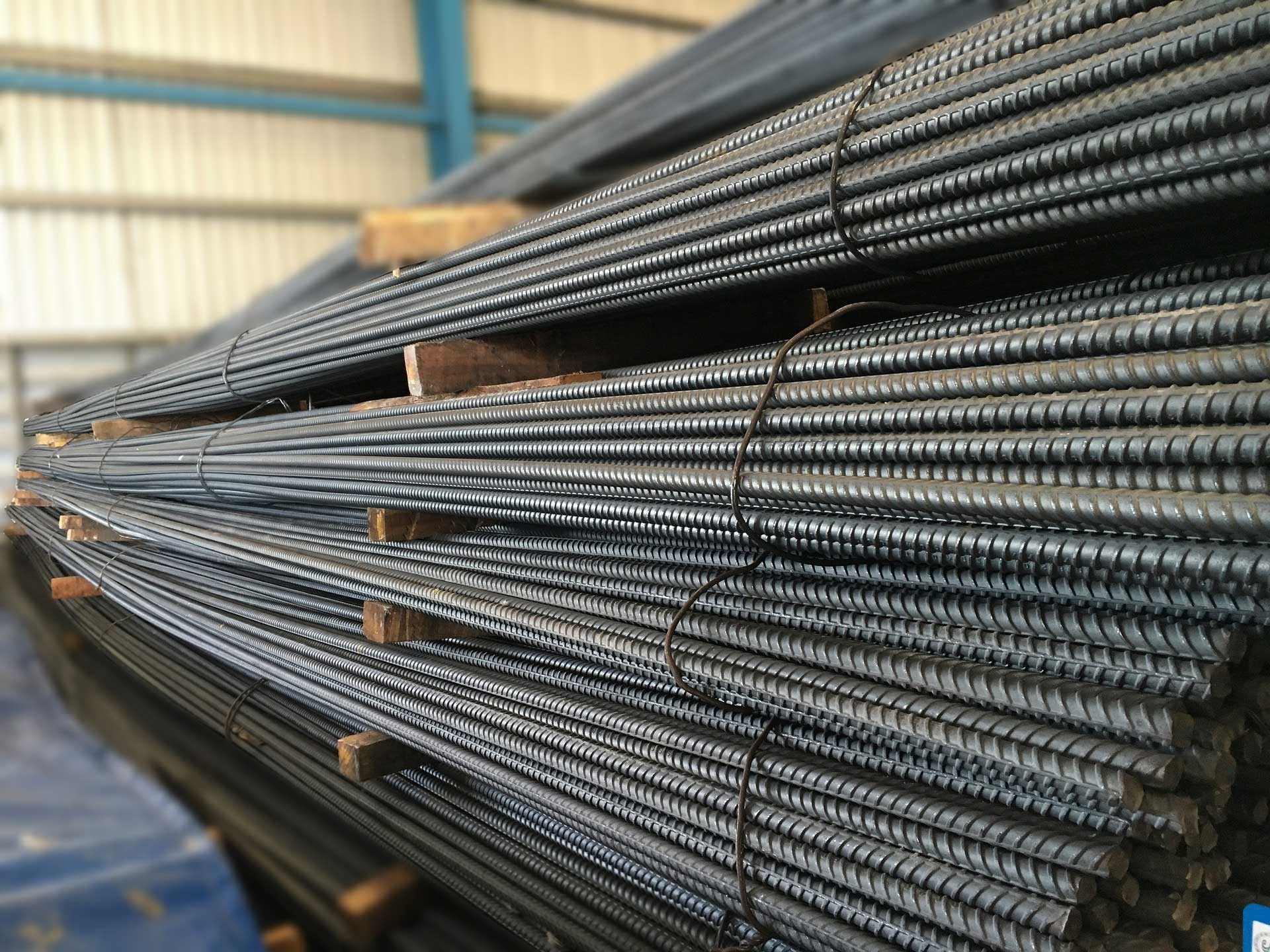

Unveiling the Dynamics of Construction Costs: Navigating the TMT Steel Price Landscape

Introduction:

In the steadily developing world of construction, where strength and durability are fundamental, Thermo-Precisely Treated (TMT) steel stands as a vital material. TMT steel is generally utilized in construction projects, giving improved strength and resilience to structures. This article dives into the factors influencing TMT steel prices, their economic implications, and strategies for navigating the landscape of construction costs.

Understanding TMT Steel:

Thermo-Precisely Treated (TMT) steel is a sort of reinforced steel that goes through an exceptional manufacturing cycle to upgrade its strength and flexibility. The interaction includes oppressing the steel bars to controlled thermal and mechanical medicines, conferring superior mechanical properties. TMT steel is portrayed by its high rigidity, great bendability, and protection from exhaustion.

Factors Influencing TMT Steel Prices:

- Raw Material Costs:

The cost of raw materials, fundamentally iron ore and salvaged material, essentially impacts TMT steel prices. Fluctuations in the prices of these raw materials, driven by market dynamics, supply and demand, and international factors, can affect the general cost of delivering TMT steel.

- Manufacturing and Processing Costs:

The cost of manufacturing and processing TMT steel, including energy expenses, labor costs, and technological speculations, adds to the last market price. Propels in manufacturing advances and proficient creation cycles can impact the seriousness of TMT steel prices.

- Market Demand and Supply:

TMT steel prices are intently attached to market demand and supply dynamics. Expanded demand for construction projects, infrastructure advancement, or modern exercises can drive up the prices on the off chance that the supply can't stay up with the flood in demand.

- Global Economic Conditions:

The general soundness of the global economy assumes a critical part in deciding TMT steel prices. Economic development and expanded construction exercises can invigorate demand for TMT steel, possibly prompting greater costs, while economic slumps might make the contrary difference.

- Technological Innovations:

Progresses in manufacturing advances and innovations in TMT steel creation can impact prices. Efficiencies acquired through technological upgrades might add to cost reserve funds, permitting producers to offer cutthroat prices in the market.

Economic Implications:

- Construction Costs:

TMT steel prices straightforwardly influence the construction costs of projects where reinforced steel is a basic part. Builders and contractors should cautiously evaluate TMT steel prices as they contribute fundamentally to the general financial plan for construction endeavors.

- Land Advancement:

Designers engaged with land projects are especially delicate to TMT steel prices. Fluctuations in steel prices can impact project courses of events, spending plan allotments, and the general profitability of residential or commercial developments.

- Infrastructure Projects:

Enormous scope infrastructure projects, like bridges, highways, and dams, vigorously depend on TMT steel for primary reinforcement. Changes in TMT steel prices can affect the cost projections of infrastructure projects, possibly influencing government spending plans and courses of events.

- Consumer Affordability:

The cost of TMT steel adds to the general affordability of lodging for consumers. As construction costs increase, engineers might give these expenses to homebuyers, influencing the openness of lodging for specific sections of the populace.

Navigating TMT Steel Price Fluctuations:

- Vital Sourcing:

Builders and contractors can participate in vital sourcing by laying out long haul associations with solid TMT steel providers. This approach can give dependability in valuing and guarantee a steady supply of value materials.

- Hedging Strategies:

Some construction industry members might explore hedging strategies to moderate the effect of TMT steel price fluctuations. This includes going into monetary agreements to secure prices, giving a level of sureness in obtaining costs.

- Market Intelligence:

Remaining informed about global steel market patterns, economic indicators, and international occasions is significant for organizations impacted by TMT steel prices. Market intelligence empowers partners to expect potential price changes and pursue informed choices.

- Contractual Agreements:

Builders and contractors can arrange contractual agreements with providers that give lucidity on estimating components. Fixed-price agreements or agreements with price change statements in view of market files can give a degree of consistency.

- Alternative Materials:

Exploring alternative construction materials that might be less delicate to price fluctuations can be an essential methodology. While keeping up with primary respectability, builders might think about materials that offer cost solidness despite unstable steel prices.

Conclusion:

The valuing dynamics of TMT steel have broad implications for the construction business, influencing the cost, plausibility, and profitability of projects. As a principal material in underlying reinforcement, TMT steel prices are dependent upon different factors, including raw material costs, manufacturing expenses, and market demand. Navigating this landscape requires an essential methodology, from sourcing to contractual agreements and hazarding the executives strategies. In the powerful world of construction, understanding the factors molding TMT steel prices enables industry players to settle on informed choices, encouraging resilience and flexibility notwithstanding market fluctuations. As construction rehearses advance, the job of TMT steel stays basic in building structures that stand as demonstrations of strength, durability, and ingenuity.

#tmtsteelprice #besttmtprice #tmtsteelrate

0 likes · 0 comments

BusinessLilly Singh

2 years ago

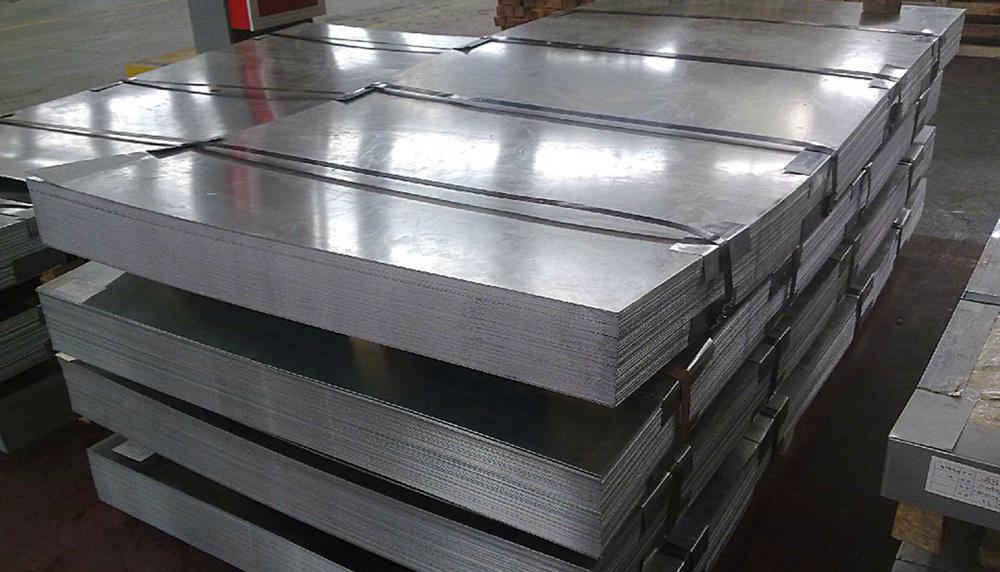

The Resilience of Construction: Unveiling the Strength of GI Sheets

Introduction:

In the realm of construction, where structures face steady environmental difficulties, Galvanized Iron (GI) sheets arise as a strong partner. GI sheets are steel sheets coated with a layer of zinc through a cycle called galvanization process, offering a strong answer for the inescapable danger of corrosion. In this article, we dig into the characteristics, applications, and advantages of GI sheets, enlightening their vital job in sustaining structures and guaranteeing longevity despite different construction challenges.

Understanding GI Sheets:

Galvanized Iron sheets, ordinarily known as GI sheets, go through an extraordinary course of galvanization, wherein they are coated with a layer of zinc. This zinc covering goes about as a defensive shield, making an impressive boundary against corrosive components. The outcome is a material that flaunts upgraded strength as well as shows exceptional resistance to the corrosive impacts of moisture, oxygen, and environmental contaminants.

Key Characteristics of GI Sheets:

- Corrosion Resistance:

The essential trademark that separates GI sheets is their remarkable resistance to corrosion. The zinc covering goes about as a conciliatory layer, defending the basic iron from the corrosive powers of the environment.

- Durability and Longevity:

GI sheets embody wonderful durability, contributing essentially to the longevity of structures. Their corrosion-safe properties guarantee that structures sustained with GI sheets keep up with their structural trustworthiness over an extended period.

- Versatility:

GI sheets exhibit versatility in application, pursuing them a favored decision for an expansive range of construction projects. From roofing to cladding and structural framing, GI sheets adjust consistently to assorted construction needs.

- Ease of Fabrication:

GI sheets are known for their ease of fabrication. Developers and producers can cut, shape, and control these sheets to suit explicit design prerequisites, allowing for flexibility and customization in construction projects.

Applications of GI Sheets:

- Roofing and Cladding:

GI sheets are widely utilized in roofing applications. Their corrosion resistance, combined with durability, pursues an optimal decision for safeguarding structures against the components. Furthermore, GI sheets track down application in cladding, adding to both tasteful allure and structural resilience.

- Structural Framing:

GI sheets assume an urgent part in structural framing. Whether utilized in walls, support beams, or other burden bearing components, the corrosion-safe nature of GI sheets adds to the soundness and longevity of the construction.

- Fencing and Enclosures:

Because of their durability and resistance to corrosion, GI sheets are a phenomenal decision for fencing and enclosures. They give a strong and persevering answer for making boundaries, adding to security and protection.

- Automotive and Modern Applications:

GI sheets track down applications past construction in the automotive and modern areas. Their strength and corrosion resistance make them reasonable for manufacturing components for vehicles and modern equipment.

Advantages of GI Sheets:

- Corrosion Protection:

The essential benefit of GI sheets lies in their unrivaled protection against corrosion. The zinc covering goes about as a vigorous hindrance, fundamentally diminishing the gamble of structural harm brought about by corrosion.

- Long-Term Cost Efficiency:

While the underlying interest in GI sheets might be higher than untreated iron, their long-term cost efficiency becomes obvious over the lifespan of a design. Decreased maintenance and substitution costs add to the monetary advantages of utilizing GI sheets.

- Versatility in Design:

GI sheets offer versatility in design and fabrication. Their flexibility allows for simple molding and customization, enabling planners and manufacturers to meet explicit stylish and structural prerequisites.

- Environmental Sustainability:

The zinc covering on GI sheets is recyclable, lining up with environmental sustainability. Furthermore, the durability and longevity of GI sheets add to reasonable construction rehearses by lessening material utilization and waste.

Conclusion:

In the constantly changing scene of construction, where difficulties request imaginative arrangements, GI sheets stand as a shield of strength. Their corrosion resistance, durability, and adaptability make them irreplaceable in bracing structures against the unforgiving components of the environment. From giving solid roofing answers for building up structural frameworks, GI sheets keep on assuming a vital part in guaranteeing the strength and longevity of constructions. As construction rehearses develop, the persevering through strength of GI sheets stays a foundation in the journey for structures that encapsulate durability, usefulness, and sustainability.

0 likes · 0 comments

BusinessDo you want to manage your own group?